- Home

- Manufacturing Power

- Engine Manufacturing

-

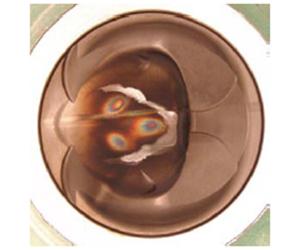

Single cylinder optical research engine

Single cylinder optical research engine

-

Salt spray chamber

Salt spray chamber

-

Air flow bench

Air flow bench

-

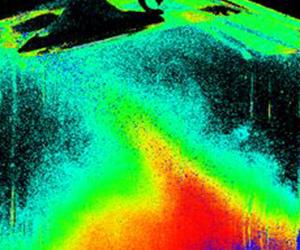

Laser measuring equipment

Laser measuring equipment

-

Fiber optic sensor

Fiber optic sensor

Optical engine testing

-

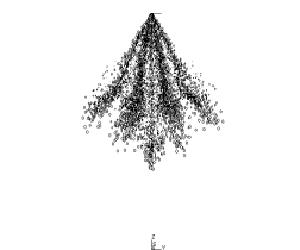

Fuel dilution

Fuel dilution

-

Fuel dilution

Fuel dilution

-

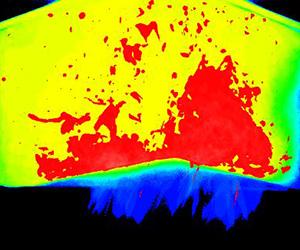

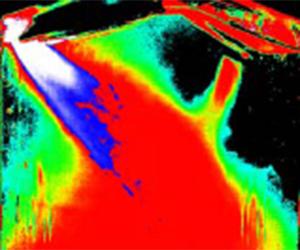

Flame of soot

Flame of soot

-

Flame of soot

Flame of soot

Salt spray simulation

-

Salt spray test

Salt spray test

-

Salt spray test

Salt spray test

-

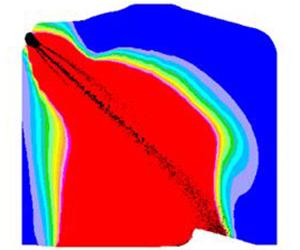

Salt spray simulation

Salt spray simulation

-

Salt spray simulation

Salt spray simulation

Air flow field analysis

-

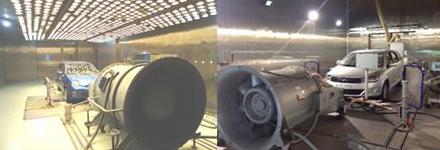

Semi-anechoic chamber

Semi-anechoic chamber

-

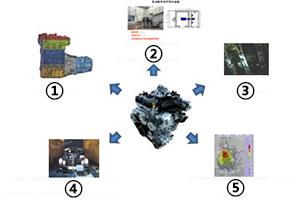

① NVH simulation

① NVH simulation

② Testing in semi-anechoic chamber

③ Vibration testing

④ Powertrain & Vehicle NVH calibration

⑤ Near-field noise source identification

-

Artificial head measurement system from HEAD ACOUSTICS

Artificial head measurement system from HEAD ACOUSTICS

-

Torsional vibration testing from BBM (16&32 channel)

Torsional vibration testing from BBM (16&32 channel)

-

Vehicle tracking and speed measurement system (VTSM) (rotary rate: 6, simulated channel: 8)

Vehicle tracking and speed measurement system (VTSM) (rotary rate: 6, simulated channel: 8)

-

Acoustic camera

Acoustic camera

-

LMS testing system (channel: 8&24&40)

LMS testing system (channel: 8&24&40)

1. Accumulation of vibration and noise, modal testing, vibration mode analysis, TPA (transfer path analysis)

2. Precise quantitative analysis for the combustion noise of engine

3. Near-field and far-field acoustical holographic testing for precise identification of noise source

Developed throttle system

CEMS 1.0: 4-cylinder gasoline engine

CEMS 2.0: 3-cylinder gasoline engine

CEMS 2.1: 3-cylinder non-road engine (KHI)

CEMS 3.0: 4-cylinder CNG (compressed natural gas) system

CEMS 5.0: 4-cylinder start-stop system for gasoline engine

Developing electronic throttle control system (Double vvt & port de-activation valve)

CEMS E1.0 : 4-cylinder gasoline engine

CEMS E1.001: 4-cylinder gasoline engine for extended-range electric vehicle

Developing throttle system

CEMS 7.0: 2-cylinder gasoline engine

Electronic throttle control system will be started within 2 to 5 years

CEMS G1.0: 4-cylinder gasoline engine

CEMS G2.0: 3-cylinder gasoline engine

-

ES630 air/fuel ratio gauge

ES630 air/fuel ratio gauge

-

Knock calibrating equipment

Knock calibrating equipment

-

Misfire generator

Misfire generator

-

Oxygen sensor simulator

Oxygen sensor simulator

-

ECU event data recorder

ECU event data recorder

-

Engine bench

Engine bench

-

Low-temperature rotating drum

Low-temperature rotating drum

Min. Temperature: -40℃

2-drive or 4-drive -

High-temperature rotating drum

High-temperature rotating drum

Max. Temperature: +60℃

2-drive or 4-drive -

Discharging rotating drum

Discharging rotating drum

Room temperature or low temperature

2-drive or 4-drive

Allocation period for brand new engine or brand new vehicle: 19.5~26.5 months

Periods of engine's batch production or vehicle's remodeling: 12~18 month

Above time could be adjusted according to different configuration, requirements and risk grade.

-

Engine batch testing room

Engine batch testing room

-

Rotary drum testing room

Rotary drum testing room

-

Trail-production workshop

Trail-production workshop

Testing facilities

Engine bench testing room (50-660kW)

Semi-acoustic chamber

Air flow bench

Valve train

Testing room for optical engine

Testing room for high-, low- and room temperature rotating drum

Dedicated trail-production room

Testing projects

Development and calibration testing for thermodynamic

Performance testing

Reliability testing

Semi-acoustics NVH testing

Air-flow testing

Dynamic testing for valve train

Optical engine testing

Rotating drum testing for the vehicle

Trail-production for component